Main Takeaways from this Article:

Sublimation printing creates vivid, full-color designs ideal for polyester or polymer-coated surfaces. Best for apparel, mugs, tiles, and souvenirs. However, it’s unsuitable for cotton or dark fabrics and requires UV protection.

Screen printing offers high durability and bold color application, ideal for bulk apparel and signage. Limited by setup complexity and inefficiency with small or multicolor jobs.

UV flatbed printing prints directly on rigid or uneven surfaces like glass, wood, or acrylic. Excellent for custom decor and signage, but may crack under flex or peel over time outdoors without coating.

Direct-to-Garment (DTG) printing works best for cotton-based apparel and detailed, multicolor graphics. Not suitable for polyester or rough-textured fabrics.

Direct-to-Film (DTF) printing excels in transferring onto diverse fabrics, including cotton, polyester, and blends. Excellent stretchability and wash resistance. Slightly more complex transfer process.

Heat Transfer Vinyl (HTV) is great for small-scale textile decoration, like uniforms and jerseys. However, layers can peel or crack under high heat or UV exposure.

Water transfer printing (Hydrographics) is suited for 3D items with complex curves—like helmets and auto parts—but involves water tanks and can be labor-intensive.

Crystal sticker transfers offer a 3D glossy finish for promotional items but may lack durability in humid or sun-exposed conditions.

Gold/Silver Foil stamping delivers luxury effects on cards, bags, and packaging. Not washable or stretchable—only decorative and fragile.

1. Sublimation Printing

Principle: Sublimation ink is printed onto transfer paper and then heat-pressed at 180–205℃, causing the ink to sublimate and embed into the coating of polyester materials.

Equipment & Materials: Sublimation printer, transfer paper, heat press (flatbed/roller/mug press), sublimation ink, coated polyester substrates

Pros:

- Vivid colors with high resolution and gradient capability

- Ink penetrates the substrate, resulting in long-lasting, soft-touch images

- Ideal for small batch and personalized printing

Cons:

- Only suitable for white/light-colored polyester or specially coated substrates

Requires precise control of temperature, pressure, and time

Durability: Excellent (wash-resistant, but UV exposure over time may cause fading)

Color Vividness: Very high (especially on polyester)

Applications: Custom mugs, T-shirts, cushions, plaques, souvenirs

Profit Margin: Medium to high (high for personalized gifts)

2. Screen Printing

Principle: Ink is pushed through mesh screen openings onto the material using a squeegee.

Equipment & Materials: Manual or automatic screen printer, emulsion screen, ink, drying equipment

Advantages:

- Thick ink layer with excellent durability

- Low cost, ideal for mass production

- Suitable for diverse materials: fabric, paper, plastic, metal, glass

Disadvantages:

- Limited color gradients; not suitable for photo-quality images

- Complex plate-making process; high upfront cost

Durability: Excellent

Color Vividness: Medium to high

Common Applications: Logos on garments, promotional T-shirts, tote bags, signage, industrial labels

Profit Margin: High in large batches; low in small batches

3. UV Flatbed Printing

Principle: UV ink is printed directly onto materials and instantly cured by UV light.

Equipment & Materials: UV flatbed printer, UV ink (including white ink and varnish)

Advantages:

- Direct printing on wood, glass, acrylic, metal, etc.

- Supports embossed, spot gloss, and transparent effects

No need for plate-making, fast turnaround

Disadvantages:

- High equipment cost and maintenance

Requires proper pre-treatment of materials

Durability: High (UV- and water-resistant with proper coatings)

Color Vividness: Very high (especially on rigid, smooth surfaces)

Applications: Signage, decor, premium gifts, awards

Profit Margin: Medium to high (especially for niche markets)

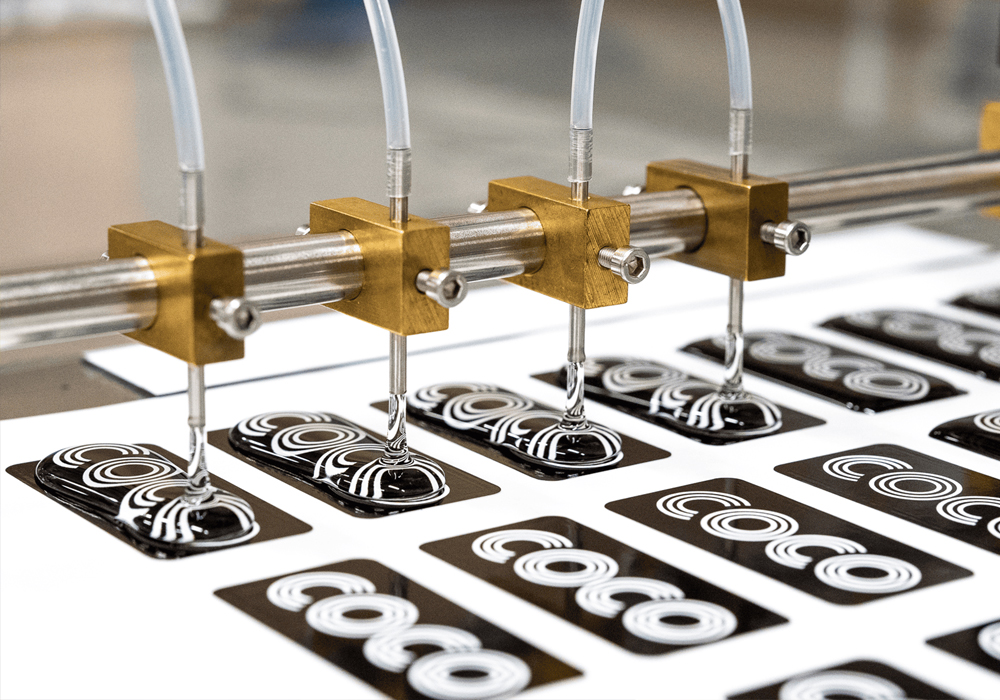

4. Resin Sticker

Principle: Images are printed on film and covered with transparent epoxy resin for a glossy, 3D effect.

Equipment & Materials: Inkjet printer, laminator, epoxy resin, dispensing tools

Advantages:

- Glossy and decorative appearance

Ideal for small-scale and customized products

Disadvantages:

- Manual resin application; labor-intensive

Susceptible to yellowing from UV and oxidation

Durability: Medium (sensitive to UV and scratches)

Color Vividness: Medium (enhanced by epoxy gloss)

Applications: Keychains, fridge magnets, labels

Profit Margin: Medium (high in small customized quantities)

5. Hydrographics

Principle: Patterns are printed on water-soluble film and floated on water. Objects are dipped to transfer the image, then coated with clear paint.

Equipment & Materials: Water tank, printed film, activator, spray gun, clear coat

Advantages:

- Perfectly fits complex 3D surfaces

Strong adhesion and color retention

Disadvantages:

- Multi-step process; environmental concerns

Large equipment footprint, high skill requirement

Durability: High (if top-coated properly)

Color Vividness: Medium to high

Applications: Auto parts, helmets, crafts, tools

Profit Margin: Medium (depends on complexity and scale)

6. Direct-to-Garment (DTG)

Principle: Water-based ink is sprayed directly onto pre-treated cotton fabric and then heat-fixed.

Equipment & Materials: DTG printer, pre-treatment equipment, dryer, water-based ink

Advantages:

- High-resolution, complex image printing

- Excellent on cotton fabrics, soft and comfortable

Single-piece friendly, zero inventory model

Disadvantages:

- High equipment cost and maintenance

Requires effective pre-treatment for wash durability

Durability: Medium to high (best on cotton with proper pre-treatment)

Color Vividness: Very high (especially on white garments)

Applications: Custom T-shirts, fashion apparel, babywear

Profit Margin: High (custom and low-volume printing)

7. Direct-to-Film (DTF) Printing

Principle: Images are printed onto PET film, sprinkled with powder, heat-cured, and transferred onto fabric with a heat press.

Equipment & Materials: DTF printer, PET film, hot melt powder, heat press

Advantages:

- Works on cotton, polyester, nylon, and more

- Bright colors, excellent wash resistance

Efficient for both bulk and single-piece production

Disadvantages:

- Thicker finish with plastic-like feel

Powder handling and storage require care

Durability: High (wash-resistant, flexible)

Color Vividness: Very high (rich and opaque)

Applications: Apparel, sportswear, hoodies, canvas bags

Profit Margin: High (low cost, flexible application)

8. Hot Foil Stamping

Principle: Metallic foil is stamped onto a material surface using heat and pressure via a mold.

Equipment & Materials: Foil stamping machine, foil, molds, heated press

Advantages:

- Eye-catching metallic gloss

Firm adhesion

Disadvantages:

- Limited image complexity; mainly text and graphics

High mold production cost

Durability: High (foil doesn’t wear easily)

Color Vividness: Bright (monochrome metallic)

Applications: Business cards, gift boxes, book covers

Profit Margin: Medium to high

9. Heat Transfer Vinyl (HTV)

Principle: PU/PVC film is cut or printed, then heat-pressed onto fabric.

Equipment & Materials: Cutter, heat press, HTV film, release liner

Advantages:

- Wide variety of special effect films (glow-in-the-dark, metallic, reflective, etc.)

- Mature process, easy operation

Ideal for text and vector designs

Disadvantages:

- Stiff texture, limited breathability

Not suitable for photo-realistic images

Durability: High (if washed gently; avoid UV and high heat)

Color Vividness: High (vibrant solid colors)

Applications: Uniforms, DIY T-shirts, sportswear

Profit Margin: Medium (especially in niche personalization)

Comparison Table

| Technology | Cost | Volume | Resolution | Durability | Color | Applications | Profit Margin |

|---|---|---|---|---|---|---|---|

| Sublimation | Medium | Small/Medium | High | Very High | Very High | Gifts, home, apparel | Medium-High |

| Screen Printing | Low | High | Medium | Very High | Medium-High | T-shirts, packaging | High (bulk) |

| UV Printing | High | Small/Medium | High | High | Very High | Signage, gifts | Medium-High |

| Resin Sticker | Low | Small | Medium | Medium | Medium | Accessories, culture | Medium |

| Hydrographics | Medium | Medium | High | High | Medium-High | Automotive, models | Medium |

| DTG | High | Small | Very High | Medium-High | Very High | Cotton apparel | High |

| DTF | Medium | Small/Medium | High | High | Very High | Apparel | High |

| Hot Foil | Medium | Medium/High | Low | High | Very Bright | Packaging, paper | Medium-High |

| HTV | Medium | Small/Medium | Medium | High | High | Workwear, uniforms | Medium |

Conclusion and Recommendations

Choosing the right printing technology depends on material type, order volume, image complexity, budget, and end-use requirements.

- For custom gifts and vibrant imagery: Sublimation, UV

- For high-resolution on cotton T-shirts: DTG

- For various fabrics and fast turnarounds: DTF

- For large-scale industrial output: Screen Printing

- For premium packaging and metallic finishes: Hot Foil

Understanding the principles, equipment, and material characteristics of each technology is key to establishing efficient workflows and sustainable profits.

Looking for a Reliable Supplier?

At Leadsub, we provide a full range of premium sublimation blanks and printing solutions. Our products are engineered for vivid color output, long-lasting performance, and seamless compatibility with professional equipment. Whether you’re producing custom apparel, corporate gifts, or souvenir merchandise, Leadsub is your trusted B2B partner.

Contact us today to request samples or discuss bulk orders!